MARTIN LOVELL gives a detailed account of how he built the first part his Narrow Gauge display layout.

MARTIN LOVELL gives a detailed account of how he built the first part his Narrow Gauge display layout.

I decided to build this layout in three parts - there was to be the quarry, a processing plant, and a distribution centre, probably a dockyard. The idea was that any of the parts could be exhibited on their own, or as a pair, or indeed all three, depending on exhibition space, and transport facilities.

They are based on a narrow gauge railway system, modelled to a scale of 4mm / ft on 9 mm track, normally known as OO9 or HOe. The baseboards measure 4ft x 2ft each so will fit in a normal car, and wired almost as a “plug and play” system, to reduce setting up time at exhibitions or at home for test purposes.>

In this account, I will endeavour to take you through the various stages of the building process. At the present time, (October 2014) the processing plant is more or less completed (but then, what layout ever is?) and has been exhibited several times, at the likes of the Amberley Museum Railway Gala Weekend (usually the 2nd weekend in July) and also at the Weald and Downland Museum back in August this year.

So here then is the story of a layout…

A rough idea for the layout as sketched out on several bits of paper until a plan began to take shape. Various factors were taken into account, namely ease of operation, adding and retrieving stock, automated features i.e. a shuttle system, and how a real processing plant would operate.

I find at lots of exhibitions some layouts have periods where nothing is happening and, lets face it this is what happens in the real world, but I feel that as members of the public, especially the non-modelling type, generally expect to see something happening. In short, to be entertained. Therefore most of my layouts past and present nearly always have something going on.

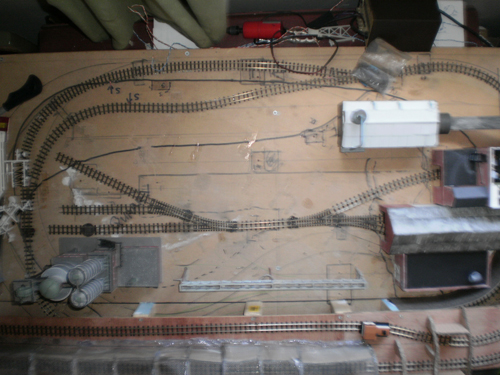

With this in mind this layout consists of a continuous loop with passing facility, a 3-way shuttle unit and the top line, which will become the line from the quarry. Hence seven trains can be operated on this small layout. The quarry line is designed so that full trains are seen to arrive, and empty trains depart. (At present to a fiddle yard, but to the quarry at a later stage, shown at bottom of picture).

I did consider having a working tipper system, but settled instead for a hidden system to give the illusion of the above. Also built into the plan were more points for the passing of trains to the third part of the layout, when this was added.

The above photo shows the track as initially laid, with scenic work having started on the hidden section below the locomotive, and the GMC-SS1 3-way shuttle unit in place.

All the points were to be electrically operated, by the stud and probe system, and various effects were also to be used - lighting and a flame effect for the boiler house. These sorts of things should be taken into account at the early stages of building a layout, so that point motors and wiring are already in place before the buildings and scenery start to arrive.

The baseboard was constructed in the standard fashion, using a sheet of half inch chipboard on a 2x1 inch softwood frame. The basic track plan was marked out, and track laying commenced. Once the lower section as laid, the upper section was built, using plywood as the track bed, on softwood supports. Whilst doing this, clearances for locos and stock could be checked to save problems later. The upper line was laid on cork sheet to cut down on the noise aspect.

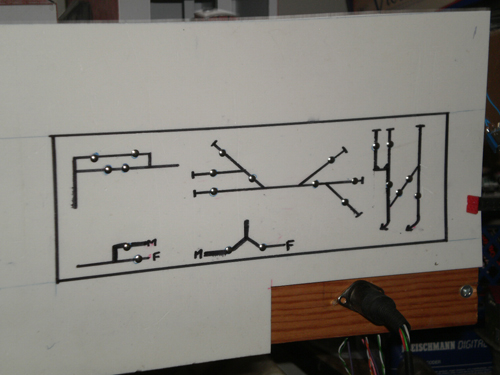

Once this was done, the track was wired up and tested, with one or two adjustments to be made (it's amazing how a dead section can suddenly spring up or points not operating correctly!) and once working to a satisfactory plan the wiring was made permanent and tidy. The points were wired to a stud and probe diagram, which is a piece of foamboard, with the bits of track plan drawn onto it.

By touching the small silver studs with a probe the points are thrown in the appropriate direction. (Wiring diagram available) Note also the plug and socket underneath the plan, this is the main feed from the controller to the whole layout, with the power for the upper and lower main tracks and the point motors. A separate controller is used for the shuttle unit and the lighting.

As most of the buildings on the layout were to be scratch built, space was only left on the plans for the two kit built structures, namely the processing plant (bottom left on track plan picture, built using a Faller Cement Works) and the boiler house (centre of layout, made out of two Dapol Engine Sheds). The rest of the structures were built to fit. If you are using ready-made buildings, or indeed kits, it is a good idea to position these on the layout (or at least make a template of the base) so that clearances can be checked.

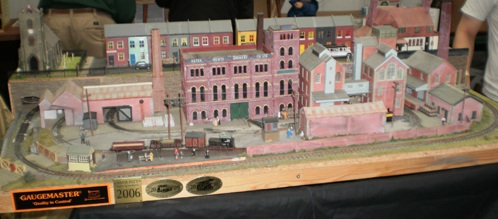

I once was building a brewery layout with the aim of scratch building the main structures, and having laid the track there then appeared on the market a model brewery, which would save time I thought, so the kit was purchased and built. I then found that the finished kit would not actually fit anywhere on the layout! So up came the track, and had to be re-laid. A lesson to be learnt I feel!

Mind you, the layout turned out all right in the end (see below).

However, onwards.

The next stage was to start on the construction of the buildings. I had already drawn up a rough plan of the type of buildings required, so out came the plasticard, straight edge etc. and construction commenced.

The plan of operation of the layout was that loaded trucks would be delivered to a tipping area, and the ore would be delivered to a sorting shed. Once sorted and crushed, the waste material would be passed to a hopper for dumping, and the pure ore would pass to the retort house for transformation into treacle (yes, treacle does come from a form of rock, really!)the raw treacle would then be passed via pipe to the processing unit, where it can be stored and packed for shipment to customers. This gives the basic layout for the buildings required.

If planning an industrial type layout, this sort of thinking makes the layout feasible, as most industrial sites are laid out to save transport time, i.e. raw material to works, works to processing, processing to finishing, finishing to packing, packing to despatch and so on. An internal rail system would have been used for linking up a lot of these processes, at least until the advent of the conveyor belt or forklift trucks.

As I wrote earlier, most of the buildings on this part of the layout are built from scratch using plasticard, both plain and embossed, although you may prefer to use card - or stick to kits (no pun intended!).

I shall therefore attempt to describe the basic building of these structures. A building, however complex, is basically a series of boxes with a lid, so constructing buildings means arranging a selection of boxes into a defined shape. I tend to check reference books, or photograph industrial sites (with permission of course) to get an idea of the sorts of buildings involved. When taking photographs, try to include a person or object of known height, to give an idea of scale when measuring up your building. Rough measurements can also be taken using a door height (roughly 6ft 6inch) or a vehicle to get some idea.

For construction, the following tools are recommended:

(Most items available in the Gaugemaster Tools Range)

Glues are down to personal preference, I tend to use the solvent type plastic adhesive which welds the plastic together, applied with a brush, but you may prefer a tube or fine applicator, whatever you are comfortable with. I usually start by working out the “footprint” of the building, i.e. the area that the building will occupy, so I can check clearances if the track has already been laid, and once that is done building can commence.

The sides of the building, once measured, can then be cut out. Any windows, doors, brick or stone work etc. can be dealt with, and then the sides can be glued together. This is where a set square comes in useful. The roof is then added, with the appropriate finish (corrugated iron, tile or slate) and then painted and weathered. Quite a simple process written down, it takes a bit longer to actually do however!

During construction you may decide to add an interior, or lighting, so take this into account during building. Details such as doors, windows, guttering etc. are readily available from various companies, as are tables, chairs, office equipment, workshop equipment and other internal details. Check our website for more details. Painting and weathering will be described in a separate article, as will a more in depth report on scratch building, watch this space. But here is a small corner of the layout to show the effect.

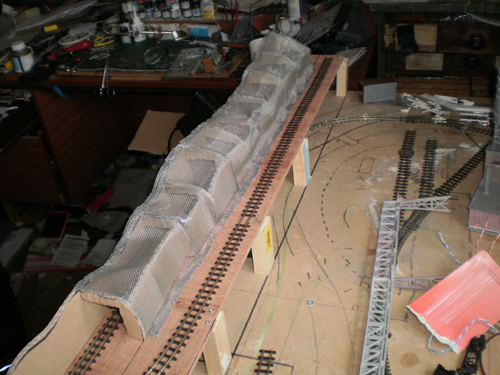

The next stage on my layout was to start on the scenic work. There wasn’t too much of this to do, but I did have to construct the hidden line plus the road access to the plant. I now tend to use box cardboard as the scenic support, as it is easy to come by, light and if using a good quality glue, very strong. You may be more used to using polystyrene or other substances, but once again this is down to personal preference.

The subject of scenery construction is covered more fully in another article in this series, so I will keep this fairly short. The cardboard is cut to size and glued in position, I personally use a hot glue gun, as this sets very quickly, checking all the time for clearance if covering the track, as below.

The card is then covered with FA170665 aluminium wire mesh, formed into shape, and attached once again with hot glue.

This can then be covered in Plaster Bandage (also known as Mod Roc) to form the skin on which to add grass mat or whatever. NOTE - When adding the plaster bandage, make sure the track is protected, as a drip of plaster can cause all sorts of running problems!

Also, although I haven’t done it yet on this picture, make sure you have access to any hidden track for cleaning, and for retrieving derailed stock, it’s pretty much guaranteed that any derailment will happen somewhere you cant get to!

Here we see the plaster bandage applied, and ready to receive the next stage of scenic work.

And here is the next bit. The grass mat has been cut and glued to the plaster shell, ready for more detailed work later. Also awaiting is the bare plaster ready for detailing with rock effects, and the track ballasting. As already mentioned, scenic construction will be covered more fully in another article. That’s all for now. I will be reporting on the construction of the quarry layout next, which involves a more complex track system, incorporating a 45 degree operating table lift, a bit like a cliff railway, but for transporting wagons. Hmm.

Happy modelling,

Martin

Martin works full time in our shop, often hiding out of sight to ambush customers with his photo album...