STUART JORDAN talks to John Bristow, owner of Deluxe Materials.

STUART JORDAN talks to John Bristow, owner of Deluxe Materials.

Stuart Jordan: Deluxe Materials have been a part of the modelling hobby for over 40 years, what changes in the modelling World have you observed in this time?

Vivienne and John Bristow of Deluxe Materials.

John Bristow: There have been some big drivers that have driven changes in many parts of the hobby. These include:

We are not involved with radio control equipment, however we have had to stay ahead of changing materials. Initially we have developed advanced products for plastics, foam, carbon fibre and composites. These include easier to use adhesives and applicators, and finishing materials to enhance appearance. Although models are ready made they still need specialist products for repairs.

DLAD-57 Roket Card Glue is our best-selling product from the Deluxe Materials range, mainly because there aren't many British layouts without a Superquick kit on it!

SJ: Have your research and development methods changed since the beginning?

JB: Considerably. The last 5 years we have taken a much more thorough approach to what we do and to new products we develop. We have developed our own internal testing methods, for example, tests for penetration and strength (of glues) and fuel resistance of finishes. Packs are also critical, so we are always testing new packs and bottles. As we have the knowledge of how a product should perform, it has been possible to search for new innovative solutions to modelling problems, using safer chemicals and formulations. Some great recent advances have been a non-toxic plastic adhesive called DLAD-43 Roket Plastic Glue, and DLBD-44 Perfect Plastic Putty, a safe water based putty alternative to other flammable products.

SJ: What processes lead to the decision to produce a product, is it your own personal preference or feedback from customers?

JB: Technology evaluation and availability are key to the process, of course, but it has to be consumer driven. Market research is however key to the process. You can’t work off hunches; it is too risky to do that! Hence we start with ideas of our own and combine them with outputs from a brainstorming process involving the trade and modellers. We use props to present product concepts and the session both refines those concepts and generates new ones. We can also develop product names that way. Usually and not surprising our modelling participants have better ideas than our own.

Sometimes we find a good product name so we will work up a label ready for when the technology comes along. Once we have a prototype product which we are confident, we will field test it privately with a few trusted modellers and take their inputs. Last year DLAC-22 Strip Magic our innovative paint stripper was good example was it to be "PAINT OFF" OR "STRIP MAGIC"? Research with consumers told us it should be Strip Magic.

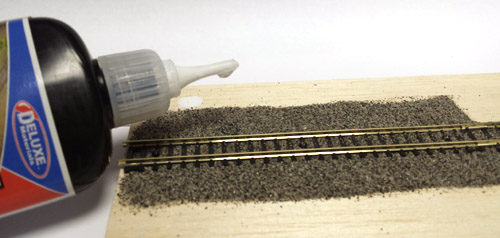

Ballast Bond was tested by us here at Gaugemaster, and our feedback helped John refine the final product.

Consumer trials: here we take the branded product to consumer shows to gauge the reaction of the modeller and to note down all we are told, positive or negative. After this we will finalise label design and words and generate all the safety and international labelling. It is then ready for launch at the Nuremberg Toy Fair, if all goes well this is an 8 month process starting May/June and ending Feb the following year. Gaugemaster and some dealers have given us some great help over the years with this process. We are most grateful for this partnership that has enabled us to launch over 32 new products in last 5 years.

SJ: How do you think being Chemists has affected the way you work?

JB: It’s enabled us to develop the right chemistry for the products we felt were needed in the market and to fine-tune them ourselves. Also this unique insight has enabled us to develop safer formulations for modelling. Perfect Plastic Putty our safe water based putty, DLAD-62 Roket Plastic Glue the World’s first non-flammable, non-toxic glue for plastics that children can use, DLAC-19 Brush Magic our airbrush and paint brush cleaner that washes away with water and is economical and safe to use are all good examples. A knowledge of modelling and chemistry has also enabled us to find the right solutions for some hard technical challenges:

SJ: What new Deluxe Materials products are in the pipeline?

JB: Next year we are taking a break from producing new products to concentrate on a few improvements to the formulations of some of our existing products. We have already identified the technology - safer resin technology and some unique water soluble polymers for working with card and paper. They require considerable investment to get them to market. However we believe in them and know they will be well received. Hence we are in the final stages of formulation work right now.

Looking 18 months ahead we already have a long list of possible new products and there are at least nine on the horizon. There is not enough time in the day!

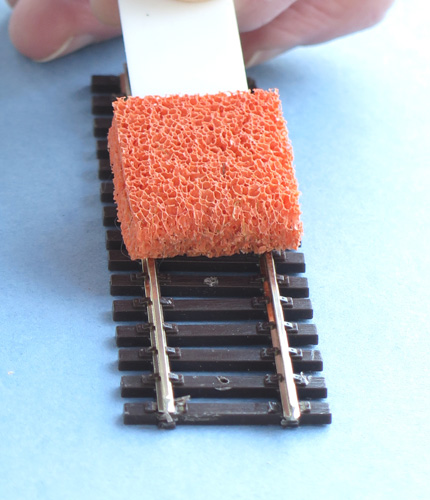

Track Magic has revolutionised track cleaning.

SJ: Which of your products are you most proud of?

JB: That is hard to say so here are few:

SJ: You produce products for Military Modellers, Railway Modellers, Dolls House Makers, Radio Control Enthusiasts, which group do you find are more receptive to trying out new products and ideas?

JB: Railway and Doll House modellers.

Railway modellers because of the challenge that comes from mechanisation and the constant demand for greater realism. There is a huge skill base in this country and a capability and willingness to try out new ideas.

Dolls house modellers are the most inventive of all and the challenge of scale, soft materials, safety, and simplicity in use is unique.

SJ: What does the future hold for Deluxe Materials?

JB: A great future for many more years. The unique combination of being modellers and chemists will enable us to continue for some time. We are going to continue to grow including overseas. Great partners around the globe like Gaugemaster allow us to concentrate on developing the right products while they handle the sales and distribution.

SJ: And finally, what is the most inventive use of one of your products that you have seen?

JB: Good question!

We recommended DLAD-29 Tacky Wax to an MSc Conservation student that needed to study the behaviour of beetles. It was to attach a miniature recording device to the beetle’s back to withstanding movement behaviour such as burrowing in leaf litter and brushing against twigs without harming it. The beetle must have escaped as I am still waiting for the recording data!

SJ: Thanks very much for your time John.

To see the full Deluxe Materials range CLICK HERE