STUART JORDAN looks at finishing and modifying N Gauge kits in the Kestrel Range.

STUART JORDAN looks at finishing and modifying N Gauge kits in the Kestrel Range.

The Kestrel range of N Gauge plastic kits are great economic way of adding buildings to your N Gauge layout, but with a bit of extra work with paints and a modelling knife you can really add something special to your layout. I'm not going to be overly specific with my methods, as I do think a lot of the fun of modelling is trying things out for yourself in order to make a unique model. Hopefully this article will be more inspiration than instruction!

Although the Kestrel Kits are pre-coloured they can always do with a bit of extra work to bring out the detail. I'm going to apply this thinking to the GMKD04 Church with Porch, painting and weathering it to make it look better than the basic unpainted kit.

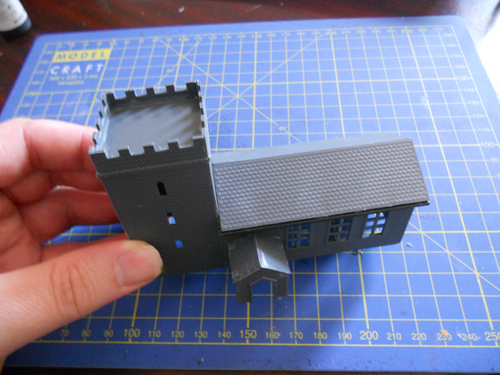

The unpainted, but built, kit.

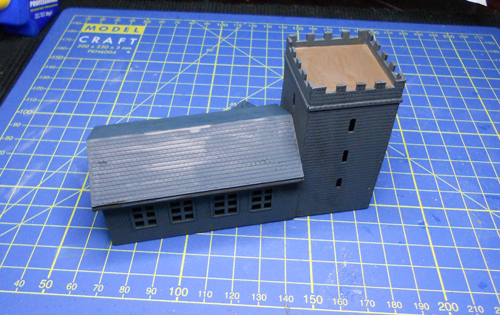

Over a sprayed-on black undercoat, a grey basecoat is brushed onto the stone, and a blue-grey basecoat over the tiles.

A lighter grey is drybrushed onto the stone and the tiles to bring out the details.

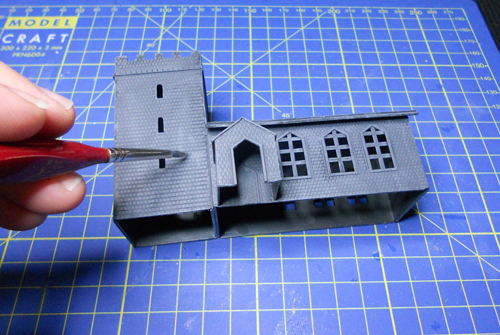

The door is painted, and small amounts of weathering powder are added to represent moss etc.. With a quick spray of matt varnish to hold the weathering powder the kit is finished and ready to be put on the layout.

One of the advantages of plastic kits is that they can be easily converted and mixed together. The parts in the GMKD06 Two Shop Unit with Glazing and the GMKD25 Corner Shop kits can, with a bit of work, be combined to create one large shop with a multiple frontage.

The two kits as advertised.

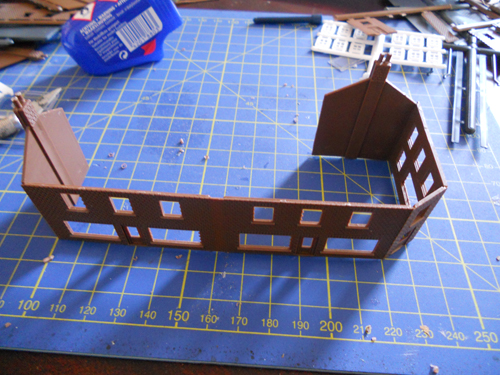

The basic wall plan is built up, with some parts cut down to fit.

The completed walls. The roof is then added, with a bit of work with a modelling knife required at the back around the bend in the building to get it to fit.

The kit is finished with painting, and signage made on the computer. After varnishing I fixed on the large window glazing with Deluxe Materials Glue N Glaze.

The easiest way to adapt a Laser Cut Shed is to give them a quick coat of paint which can give a different finish, adding variety if you are using multiple sheds in a row of gardens. As these are pretty small when built you will probably need to fix it to a thin bit of wood or a nail head with blue tack or double-sided tape to avoid having to handle the shed while painting it.

For this example I have used a Kestrel Garden Shed.

A wash of watered down mid-brown paint can make it look like it's just received a coat of creosote.

A drybrush with grey paint can give the shed an old weathered look, as though it has been out in all weathers for a couple of decades.

So, that concludes this article, I hope it's given you a bit of information for ideas on how to modify and finish your own Kestrel kits, Contact Us if you come up with anything! In the future I may look at other kits in the range and what can be done with them.