MARTIN LOVELL explains how to go about this essential piece of maintenance.

MARTIN LOVELL explains how to go about this essential piece of maintenance.

The essential things to have on your model railway, apart from locomotives and rolling stock - are CLEAN wheels and rails, otherwise nothing much will happen apart from aggravation.

For clean rails items such as track rubbers and various fluids can be employed - these I will come to later, but for now I’ll start with wheels and pickups.

There are many ways of cleaning locomotive wheels, depending on the drive mechanism of the locomotive in question. For example, are the motor and pickups in the tender or the locomotive? Are traction tyres used on the locomotive? Both of these lead to different ways of cleaning.

The best way to clean wheels is to have them rotating under power and then using a mildly abrasive material to remove built up dirt and grime, ensuring a clean surface in contact with the rails. Do NOT however use wire wool, as this will shed iron or steel fibres with will find their way onto magnets in the motor causing short circuits or worse.

Here at Gaugemaster we have several methods available to do the job for both N and OO/HO Scales.

GM59 for N Scale (or even Z!) or GM60 for HO/OO Scale are a plastic block with two parallel strips of wire brush connected to two metal strips that rest on the track.

By putting this on the track and applying power, the locomotive can then be lightly pressed down onto the brushes, the wheels will revolve thereby removing dirt.

Care should be taken if traction tyres are on the wheels as they may get damaged.

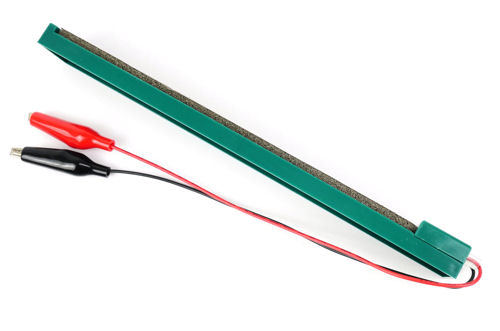

GM47 for N Scale or GM50 for HO/OO are aimed at larger locomotives, and they consist of two long strips of electrically conducting, mildly abrasive material connected to two fly leads with crocodile clips attached. The clips can then be clipped to the rails (or directly to the track output of the controller). With the loco held in position, the revolving wheels will then be cleaned.

All of the products mentioned so far can be used on either analogue or digital systems.

If the pickups are on free running wheels, the above systems however will not work, except on the wheels connected to the motor - so other methods are required.

GM633 is a 4mm Glass Fibre Pen used for burnishing metal, but equally good for cleaning dirt off of wheels. Caution is required in the use of this as the glass fibre dust is very irritating, and small splinters embedded in fingers or worse, take some removing, so if using this method, wear latex gloves or have a vacuum cleaner handy to clear the fibres as they drop.

A track rubber can also be used to gently polish the wheels, especially if they have a nice squared edge, GM26 or the larger GM27 are ideal. A fluid such as Track Magic (DLAC-13) can also be sparingly applied using a lint free cloth or cotton bud, wiped off as you go. Included in the Track Magic pack a very small applicator is included, designed for cleaning point blades but ideal for the pickup to wheel contact.

For Analogue users, a high frequency device can be used. This is connected to the track output of the controller, and if a break in contact between the track and wheel is detected due to dirt etc., the device ionises the gap and the dirt gets "burnt" away.

Do not be alarmed at this - no damage is done to the wheels, pickups or motor. In fact, any points of contact are kept clean, especially motor commutators and brushes, even in case of N gauge mechanisms. I employ these to good effect on all of my OO9 layouts.

The GMC-HF1 (single track) and GMC-HF2 (dual track) cannot however be used on digital circuits, and sometimes a locomotive fitted with a decoder running on an analogue circuit will not respond, as the decoder is trying to work out what this strange signal is. We advise that you take out the decoder and add the blanking plate if you are running the locomotive on analogue with a High Frequency decoder.

Having cleaned your loco wheels, do not neglect your rolling stock! It is a pointless exercise spending time and effort cleaning your loco wheels if the rolling stock is going to dump crud straight back down on the track again. I have seen rolling stock with impacted dirt thick enough to peel off like a traction tyre! So keep an eye on stock that has been running for a while, and clean in the same way as non-driven wheels.

So there we are, hopefully I’ve been able to point you in the right direction on keeping your wheels clean, and hence keeping things running, in another article I will go through rail cleaning and good electrical contacts, but till then, Happy modelling...