In this instalment, we see why TERRY SMITH has taken to building structures before the track is even laid down.

In this instalment, we see why TERRY SMITH has taken to building structures before the track is even laid down.

The first instalment was about the groundwork required to produce a layout, and we will be following how this project comes together over to coming issues of RIGHT LINES.

Normally on a layout-build, the track would go down first and scenery and structures would be built around it. However, this is slightly different - when building on smaller baseboards it is important that the structures have enough room to work in the limited space.

The main feature on this layout is the coalyard, and this means staithes. Easy right? - just purchase a plastic kit or two, lay them out and space out the tracks accordingly. Except I could not find any staithes in this scale.

Yes, I was surprised too - a gap in the market maybe? I saw a nice O Scale resin version, but it seemed expensive and I needed a least two to make the yard look worthwhile. The next option was to make my own out of plastic sheet - but hold on; we have had Balsa Wood Bundles in the Gaugemaster Scenic range for a few years, could they be the answer?

Well frankly yes, and what a wonderful and easy material it turned out to be to work with. Using just basic tools on a few evenings over the Christmas break, I not only constructed the staithes to the sizes I required but started on the coal merchant's office. I have to admit that I have never used balsa before, being part of the polystyrene kit generation, but I will certainly be looking to using it more in the future.

The Balsa Wood Maxi Bundle contained everything I needed to create my staithes and more!

For this excercise, you will also need:

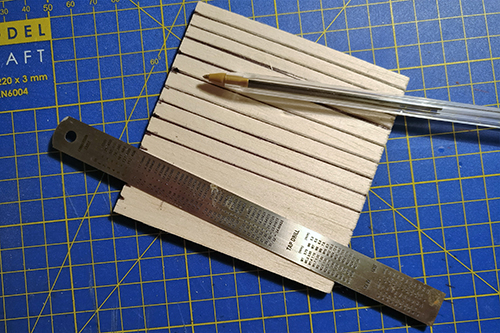

Using the one-eighth inch thick sheet I used a black biro pen to mark out the separate sleepers, the pen giving a nice realistic curve to each edge.

Using a sharp blade, I cut the tops of the sleepers randomly and the biro was again used to create the holes left by the rail chairs. The blade was then lightly dragged along the surface to create a deeper grain and signs of splits in the sleepers.

This shot shows just how much can be created from not even one sheet of the balsa.

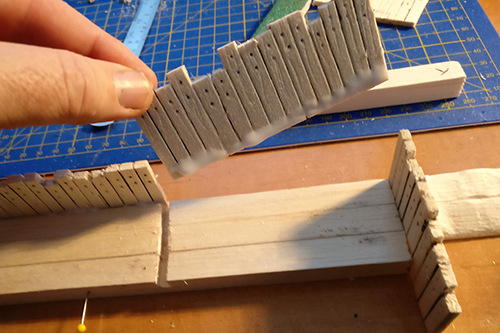

I could have just butted all the sides of the staithes together, but I decided to give the structure a little more strength by using some of the square section balsa that came in the bundle. I cut slots into them to support the sides.

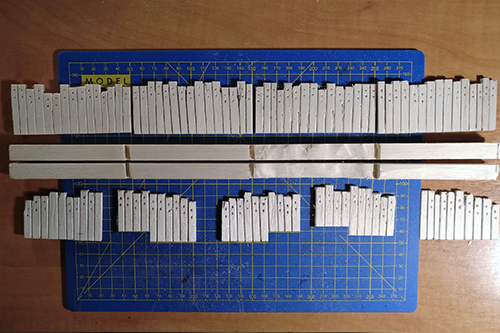

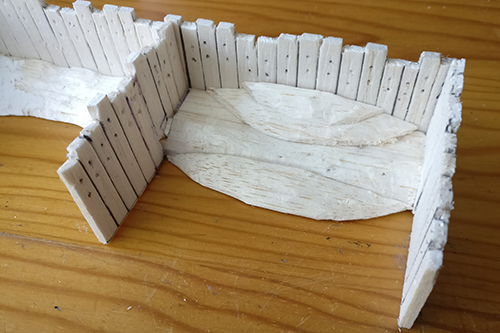

This is all the components cut to size before assembly. I decided to double up on the square section both for strength and to act as a base for the coal to go on.

A decent PVA-style wood glue like Speed Bond from Deluxe Materials was used, and pins inserted to hold everything in place while the glue dried.

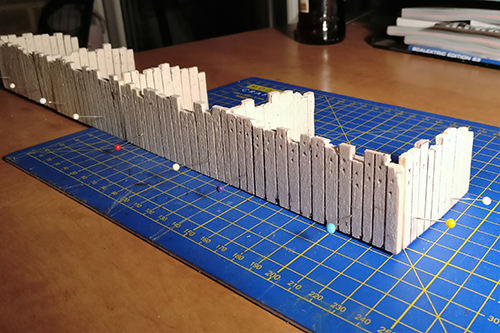

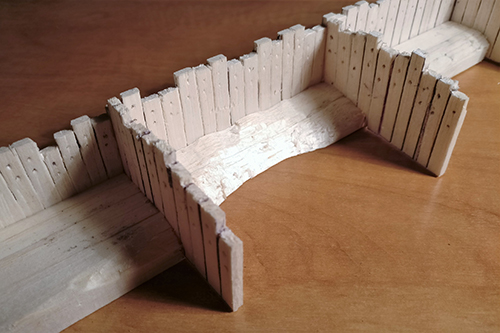

A view from the rear showing the completed model, with pins still in place.

To give randomness to each staithe, two had additional square sections were added while this one had a lot of it cut away, with the one behind was left as is.

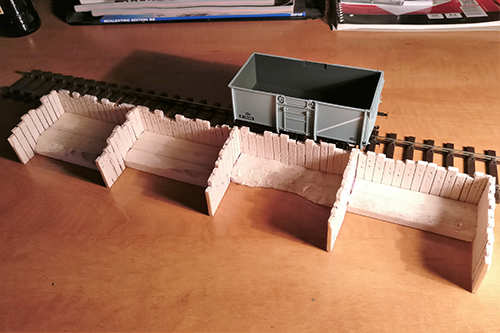

Let the dog see the rabbit! This view shows the relationship of a mineral wagon to the staithes and the differing amount of wood used in each bay.

More sculptured wood was added to each bay to cut down of the amount of filler that would be needed.

A coat of pre-mixed filler was used over the balsa forms, to represent the piles of coal.

I love it when a plan comes together! A wash of 50/50 paint and thinners was used to stain rather than paint the sleepers. The paint was a mix of black and brown.

The plaster coal piles were then painted with a coat of gloss black as a base. This will then be covered at a later stage with GM112 Coal.

The completed structure was then placed on the proposed layout baseboard and moved, along with the track, until the best position could be found.

As a footnote, I felt that the sides of the staithes encroached a little too much into space needed for coal lorries to be loaded - and since the last picture has been taken, I have trimmed a sleeper off each of the bay sides to get more clearance. – More in Part 3! Terry.